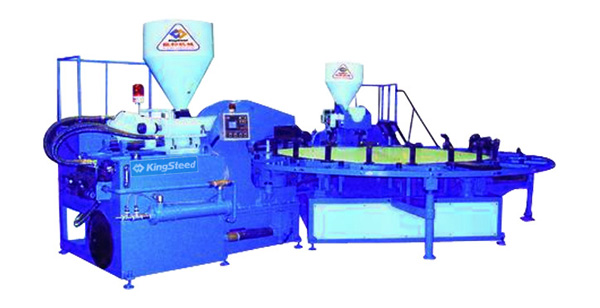

Mechanical Use:

Suitable for production of high-grade single-color and double-color soles of sports shoes,leisure shoe soles and children¨@s shoes.

Mechanical Features:

1. Suitable materials include various foaming or non-foaming thermoplastic materials,e.g.TPR and PVC.

2.Fully-automatic computer control is adopted and the main and auxiliary machinery features good stability,easy. operation,high compatibility and simple maintenance.

3. Combination of main-sub cylinder with pressure switch is adopted for dis sinking to ensure quick die sinking andfast setout of die lock force,so that there is no burr for each forming.This results in guaranteed product quality.

4.Proportional pressure control, so that the jet pressure of each die can be independently operated.This is suitable for manufacture of the products with varying jet flow.

5. Designed to meet the market demands and help the shoe manufacturers to produce for small order but of multiple styles.Less work stations (12-station and 16-station), small scrw (Main screw£ºØ45£»Auxiliary screw£ºØ40), compact motor (11KW/15HP), time saving and power saving,especially suitable for manufacture of single-and double-colr soles of children¨@s shoes, Less space occupied(7.3m/4.7n).

TECHNLCAL DATA

|

Model |

Unit |

KS-216 |

|

Number of work station |

Stations |

16 |

|

Produtivity per hour |

Pairs |

150-200 |

|

Sorew diameter |

Mm |

Ø45/Ø40 |

|

Max.injection pressure |

Kg/cm² |

0-110 |

|

Jet volume |

cm³ |

320/230 |

|

Mould clamping force |

Tons |

31 |

|

Mould space(L¡ÁW¡ÁH) |

Mm |

450¡Á330¡Á130 |

|

Temprature control |

Sets |

8 |

|

Motor |

KW/HP |

11/15HP¡Á2 |

|

Electric heating power |

KW |

10 |

|

Totai electric consumption |

KW |

30 |

|

Machine dimension(L¡ÁW¡ÁH) |

M |

7.3¡Á4.7¡Á2.2 |

|

Weight(Approximate) |

Tons |

9 |